|

|

|

Elite4print.com is your expedient printing online resource. Located in Carson, California, Elite4print.com offers high quality printing with competitive pricing.

Elite4print.com is quickly becoming one of the top online printing companies in California. The company boasts 2 offices over 25,000 square feet filled with top of the line machinery. The growth of this company is not only due to providing costomers with the best value and superior products, but also because of the commitment to providing excellent customer service. From business cards to banners, Elite4print.com has all the solutions to your printing needs. To keep our promise for providing clients with exceptional customer service, great products at affordable prices, Elite4print.com has invested millions. To offer customers the highest quality Elite4print.com only uses 5 and 6 color 40" Mann-Roland and Heidelberg machinery.

Through competitive pricing, first-class quality, helpful and knowledgeable customer service, and fast turnarounds, Elite4print.com makes every effort to be your single source for all your print media. Let Elite4print.com prove to you why thousands of clients are satisfied with our company and return time and time again. Elite4print.com can guide you towards a solution for your printing needs.

|

|

|

ROLAND 700 (5 Color / 6 Color)

Enlarged sheet size*. Selecting the optimal sheet size can make a big contribution to production efficiency. The 3B plus format (780 x 1,050 millimeters) available for the ROLAND 700 HiPrint accommodates more multiple-up images on a sheet.

QuickChange options*. QuickChange covers various technologies for reducing makeready times. QuickChange Coating, for instance, enables the press to be changed from UV to dispersion coating in only 15 minutes. QuickChange Surface can cut the time needed for cleaning the ink fountain by 50 percent. QuickChange Color reduces re-start waste, and QuickChange Job automatically adjusts the height of the gripper bars in the infeed drum and transferters. That's only a few of the QuickChange options available. |

Spoil-free delivery pile*. The ROLAND InlineSorter diverts any start-up waste sheets. This means that after a wash-up or a press stop, there are no spoiled sheets in the delivery pile. Time-consuming manual sorting is no longer necessary.

Non-stop operation*. With the non-stop feeder and delivery, piles are changed at production speed. This saves a great deal of time when running thick substrates in particular, and the non-stop equipment can be linked to AUPASYS, the world's leading automated pallet transport system. Besides that, the system can reduce start-up waste. |

|

Heidelberg Saddle Stitch Machine Featuring fast and easy makeready, the Stitchmaster ensures efficient finishing

up to 10,000 copies and even longer runs with constantly changing formats.

Operating at up to 9,000 cycles an hour and able to handle formats

up to 12 1/4 x 14. The robust and easy-to-operate Stitchmaster is an ideal step into saddlestitching. |

|

|

It allows print shops and binderies combine the entire production process in-house. Makeready is facilitated by a menu-driven program. The PLC control system monitors quality and controls all of the saddlestitcher's functions. Job changes are accomplished with just a few simple steps. |

|

| Product Profile |

| * Outputs up to 9,000 copies per hour |

* Up to four double vertical hoppers |

| * Upright sheets to minimize marking of finished products |

* Larger pile volumes possible |

| * Fast and easy changeovers |

* Lets printers bring the entire production process in-house |

| * Heavy duty trimmer and 2-up production |

| * Quality monitoring devices; long book, side caliper and missing stitch control |

|

|

Heidelberg Saddle Folding Machine The USA-made line of half and full size folders is the most economical folding solution in these sheet sizes. Easy set-up, fast make readies and reliable high output are the benefits of these line of folders. Standard equipment includes a continuous feeder, combination buckle plates soft PU fold rollers. All folders can be equipped with a pre-slitter shaft in the 1st station and/or a short mailing table at the fold unit exit for added flexibility. |

| Product Profile |

| * Standard continuous feeder for high productivity |

* Soft PU fold rollers for exceptional register |

| * Combination buckle plates with fine adjustments for fast make readies |

* Retrofit options to include mailing applications |

|

* Optional high-output deliveries for added speed and capacity options available. |

|

Silk Lamination Machine

High speed, one-sided laminator. Designed for the publishing, printing, and copy shop markets as a cost-effective, fully integrated system. The Delta quickly and efficiently laminates

large jobs with paper stacks up to 25" high and speeds up to 65 feet per minute. |

|

|

Heidelberg POLAR Cutter ( x 5 )

The top-of-the-line model POLAR offers numerous extra functions and modes of operation. This makes the POLAR with Auto trim the most efficient model of this construction series, permitting a 30% increase in productivity with all of the cutting programs (automatic waste removal while cutting). The POLAR high-speed cutters process material with diagonal sizes up to 115 cm (e. g. 65 x 92 cm). Reams with diagonals exceeding 115 cm (a max. sheet length of 115 cm) can be turned on the front table(or, with retractable side gauge, on the reartable). The POLAR can be combined with a stack lift, automatic jogger, buffer, gripper-loading system, and loading and unloading systems to form complete cutting systems. All of the models offer amazingly short setup times and a high output. The sturdy construction and in particular the direct precision measuring system complete the design. |

HP Scitex FB700

Large Format Printer

Print on media up to

2.5-meters (98-inches)

wide and, with the optional

extension tables, on larger

sheets up to 3-meters

(120-inches) long.

Print directly on virtually any rigid or flexible material even on

corrugated plastic with good ink adhesion.

HP Scitex FB700 product has established high standards which set it apart

from the competition. |

|

|

HP Designjet L65500 Large Format Printer

HP Designjet L65500 Printer featuring HP

Latex Inks and HP Wide Scan Printing Technology offers print service providers (PSPs) a

versatile print system that can produce a wide range of applications - from point-of-purchase

displays, transit signage, wall murals and exhibition graphics to vehicle

graphics and fleet marking, and a variety of exterior and interior event signage.

The HP Designjet L65500 Printer with HP Latex Inks produces durable outdoor and

indoor applications up to 104 inches (2.64 m) that withstand the elements while also

providing exceptional image quality at high resolution - up to 1,200 dpi. |

HP Latex 360

Large Format Printer

The HP Latex 360 Printer produces indoor and outdoor prints on a variety of traditional signage substrates even textiles. And high-quality, durable prints provide scratch resistance comparable to hard-solvent inks. The higher-volume, 64-inch HP Latex 360 Printer prints up to 978 ft2/hr and increases application versatility with an ink collector for porous textiles. The printer also features automatic front-to-back registration for printing double-sided banners. |

|

|

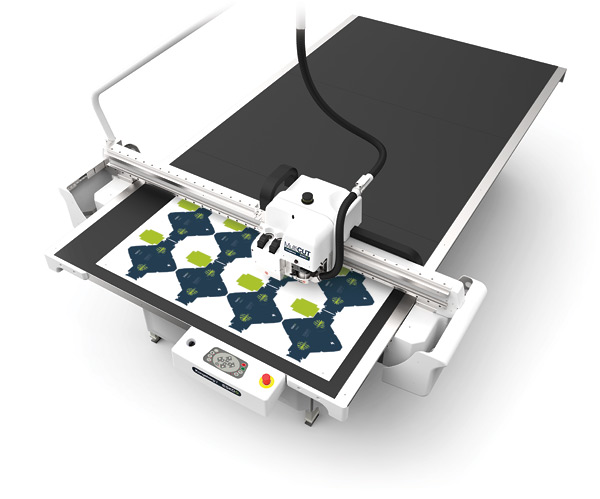

Kongsberg V - Esko

The Kongsberg V is a cutting table that stands for value, durability, reliability, precision and ease of use at an attractive investment level.

The Kongsberg V cutters come in standard configurations for sample making, signage and display production.

The Kongsberg V offers a broad selection of tools, providing quality results on a wide range of cutting, creasing, and plotting tasks. No matter what application, the Kongsberg V brings the value you are looking for.

The Kongsberg V for signage and displays comes with a MultiCUT tool head offering milling productivity and a camera system |

Triad Extreme Universal

The Triad Extreme Universal provides Blind Hemming.

The Triad Extreme Universal is packaged to meet a variety of industrial fabric welding demand. It maintains a noiseless operation and has a patented self-centering wedge for accurate product placement. |

|

|

|